Addressing this error promptly is not just a matter of resolving a technical hiccup, it’s about ensuring the smooth, uninterrupted operation of critical industrial processes. In this article, we delve into the nature of Ethernet IP Error F3 in Omron CJ2M PLCs, exploring its causes, troubleshooting steps, and preventive measures.

Understanding the CJ2M Ethernet IP Error F3

The CJ2M Ethernet IP Error F3 is a common problem encountered by users of Omron’s CJ2M programmable logic controllers (PLCs). This error typically indicates a communication error between the PLC and the network it’s connected to, often due to incorrect network configuration or PLC settings. But don’t worry, solving it might be easier than you think.

Causes of Ethernet IP Error F3 in CJ2M

The causes of Ethernet IP Error F3 can vary, but they generally fall into several categories:

- Network Configuration Issues: Incorrect IP settings or subnet masks can lead to communication failures.

- Hardware Problems: Faulty cables, connectors, or network cards can disrupt the network connection.

- Software Glitches: Outdated firmware or software conflicts can cause the PLC to malfunction.

Insights from the Omron official documents suggest that specific system configurations or external environmental factors can also contribute to this error. For example, electrical noise or interference in the industrial environment can disrupt network communications.

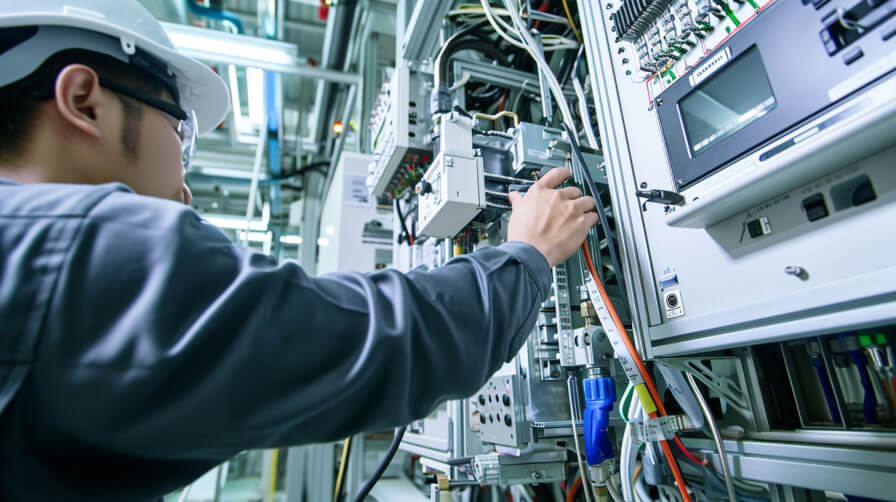

Preliminary Checks and Basic Troubleshooting

Before delving into complex solutions, certain preliminary checks are essential:

- Check Connections: Ensure all cables and connectors are secure and undamaged.

- Reboot the System: Sometimes, simply rebooting the PLC and network devices can resolve transient issues.

These initial steps are crucial as they can often resolve simple, overlooked issues that might be causing the error.

Advanced Solutions to Resolve Error F3

For more persistent issues, advanced troubleshooting is required:

- Software Settings: Check and update the PLC’s firmware and review the network settings.

- Network Configurations: Analyze and optimize the network topology and traffic to ensure smooth communication.

- Hardware Inspections: Conduct thorough checks of all network hardware components.

Referencing specific procedures from the Omron documentation will provide detailed guidance on these solutions.

Preventative Measures to Avoid Future Errors

Preventative maintenance is key to avoiding the recurrence of Ethernet IP Error F3:

- Regular System Maintenance: Perform routine checks and maintenance of the PLC and network components.

- Use of Diagnostic Tools: Implement monitoring tools to detect and address potential issues before they escalate.

By adopting these practices, the likelihood of encountering Ethernet IP Error F3 can be significantly reduced, ensuring more reliable and efficient operation of your Omron CJ2M PLC systems.

Case Studies or Real-world Examples

In the world of industrial automation, real-world examples often speak louder than theoretical solutions. Let’s look at a couple of instances where dealing with Ethernet IP Error F3 led to successful outcomes:

Case Study 1: Manufacturing Plant in Germany A German manufacturing plant experienced recurrent Ethernet IP Error F3 in their Omron CJ2M PLCs, leading to sporadic shutdowns. The solution involved updating the firmware and reconfiguring the network settings. Post-intervention, the plant reported a 90% reduction in network-related downtimes, showcasing the effectiveness of keeping software and configurations up-to-date.

Case Study 2: Food Processing Facility in Canada A Canadian food processing facility faced similar issues, with the error disrupting their packaging line. The resolution involved replacing faulty network cables and connectors, followed by a systematic reboot of the system. This simple yet effective solution led to an immediate resolution of the error, emphasizing the importance of basic hardware checks and maintenance.

These cases highlight how different approaches, tailored to the specific causes of the error, can lead to successful resolutions, greatly enhancing operational efficiency and reducing downtime.

Conclusion

In summary, Ethernet IP Error F3 in Omron CJ2M PLCs, while a common issue, can be effectively managed through a systematic approach. Understanding the error, identifying its causes, and implementing both basic and advanced troubleshooting steps are crucial.

The importance of preventive measures and regular maintenance cannot be overstated, as they play a key role in avoiding future occurrences of such errors. The case studies provided underscore the effectiveness of these solutions in real-world scenarios.

Experiencing Ethernet IP Error F3 in your Omron CJ2M PLCs or have further questions about industrial automation solutions? Our team at ikwoco is here to assist. We offer technical support, product guidance, and solution-oriented services to ensure your industrial operations run smoothly. Don’t let technical issues hinder your productivity.

Contact us at info@ikwoco.com or visit our website for more information and resources. Let us help you maintain the reliability and efficiency of your industrial systems with our expertise in Omron products. Reach out today for professional support and solutions.