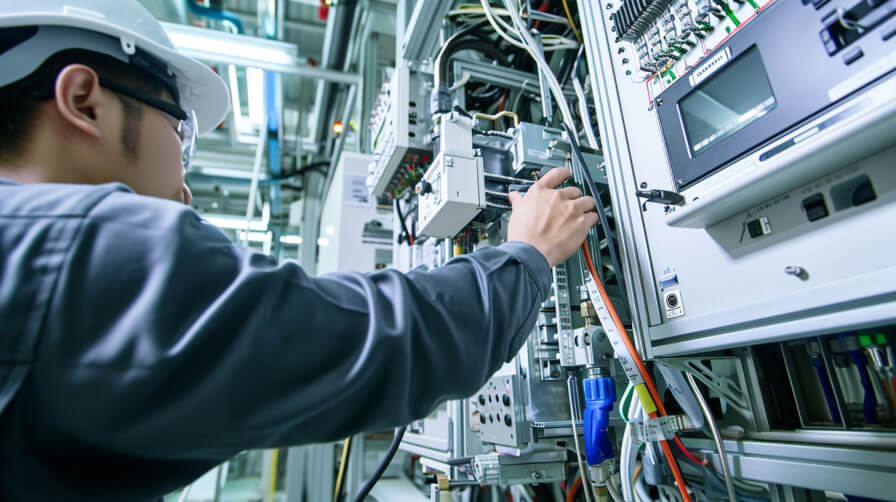

However, as with any advanced technological equipment, there are challenges. One such challenge is software compatibility, a critical aspect that can significantly impact the efficiency and functionality of these systems. Software compatibility issues in Omron PLCs can arise from various factors, leading to operational inefficiencies, downtime, and increased costs.

The purpose of this article is to delve into the complexities of software compatibility with Omron PLCs. We aim to provide practical solutions and guidance for industry professionals facing these challenges. By addressing these issues, we can help ensure that operations remain smooth, efficient, and up to date with the latest technological advancements.

Understanding Omron PLC Software Compatibility

Software compatibility, in the context of Omron PLCs, refers to the seamless integration and functioning of the PLC’s software with other system components and external applications. It’s about ensuring that the software communicates effectively with the hardware, operating systems, and other software applications used in industrial automation systems.

Several factors can lead to compatibility issues. Outdated software versions are a common culprit. As technology evolves rapidly, keeping software up-to-date is crucial to maintain compatibility with new hardware and technologies. Additionally, hardware limitations can pose compatibility challenges. Older PLC models may not support newer software versions, or their processing capabilities might be insufficient for the demands of advanced software, leading to performance issues.

Identifying Common Compatibility Issues

Compatibility problems with Omron PLCs can manifest in various forms. A frequent issue is the incompatibility between the PLC software and the operating system on which it runs. This can lead to errors in program execution, difficulties in programming, or challenges in data communication. Another common problem is the mismatch between the PLC software and the connected peripheral devices, such as sensors or actuators, which can result in inaccurate data readings or operational failures.

Case examples illustrate these issues vividly. For instance, a manufacturing plant may experience unexpected downtime due to an outdated software version in their Omron PLC, which failed to communicate effectively with a newly installed piece of equipment. Another example could be an engineering firm facing data inconsistencies due to a mismatch between the PLC software and the sensors used in a monitoring application.

In both cases, the root of the problem lies in software compatibility, highlighting the need for a proactive approach to managing these systems. In the following sections, we will explore ways to prevent such issues and troubleshoot them effectively when they arise, ensuring your Omron PLCs operate at their optimal capacity.

Preventive Measures

Best Practices for Preventing Software Compatibility Issues

- Regular Updates: Ensure that both the PLC software and firmware are regularly updated. Omron frequently releases updates to enhance functionality and address known compatibility issues. Staying current with these updates can prevent many common compatibility problems.

- Compatibility Checks: Before implementing any new software or hardware, conduct thorough compatibility checks. This involves verifying that the new components are fully compatible with the existing Omron PLC system, including software versions and hardware capabilities.

- Consult Documentation: Always refer to Omron’s official documentation for guidance on compatibility. These documents often provide detailed information on which software versions are suitable for specific PLC models.

- Professional Advice: When in doubt, seek advice from Omron professionals or authorized dealers. They can provide insights into the best software choices for your specific PLC models and applications.

Troubleshooting Software Compatibility Problems

Step-by-Step Guide on Diagnosing and Troubleshooting

- Identify the Issue: Clearly define what the compatibility issue is. Is it a communication error, a malfunctioning process, or a software crash?

- Check Software and Hardware Versions: Verify that you are using the correct versions of software for your PLC model. Ensure that all hardware components are compatible with these software versions.

- Consult Error Logs: Review the PLC’s error logs for any clues about the compatibility issue. These logs can provide valuable information about the nature and timing of the problem.

- Simulate the Problem: If possible, recreate the issue in a controlled environment. This can help in understanding the exact conditions that lead to the problem.

- Isolate Variables: Change one variable at a time (e.g., software version, hardware component) to pinpoint the cause of the issue.

Tools and Resources for Troubleshooting

- Omron Customer Support: Reach out to Omron’s customer support for expert assistance. They can offer specific advice tailored to your situation.

- Online Forums and Communities: Engage with online forums and communities where professionals share their experiences and solutions for similar issues.

Upgrading and Updating Omron PLC Software

Guidance on Safely Upgrading and Updating

- Backup Current Settings: Before any upgrade, backup all current PLC settings and programs. This ensures that you can restore the previous state if the upgrade encounters issues.

- Follow Official Guidelines: Use Omron’s official guidelines for upgrading software. These guidelines provide step-by-step instructions to ensure a smooth upgrade process.

- Test After Upgrade: After upgrading, thoroughly test the PLC in a controlled environment before deploying it back into production. This helps in identifying any unforeseen issues that might arise due to the upgrade.

Addressing Challenges and Risks in the Upgrade Process

- Compatibility with Existing Systems: Ensure that the new software version is compatible with your existing system setup, including other connected devices and software.

- Downtime Management: Plan the upgrade at a time that minimizes impact on production. Consider possible downtime and have contingency plans in place.

- Training and Adaptation: Post-upgrade, ensure that your team is adequately trained on any new features or changes in the software. This helps in smooth transition and efficient use of the upgraded system.

Expert Tips and Best Practices

Advice on Handling Software Compatibility

- Stay Informed: Keep abreast of the latest developments and updates from Omron. Subscribing to newsletters and technical bulletins can keep you informed about new software releases and known issues.

- Engage with User Communities: Participating in forums and user groups can provide valuable insights from other users who have encountered and resolved similar issues. Sharing experiences and solutions can be incredibly beneficial.

- Regular System Audits: Conduct periodic audits of your PLC systems to ensure that all components are working harmoniously. This includes checking for software updates, hardware integrity, and overall system performance.

- Invest in Training: Continuous education and training for your technical team are essential. Understanding the nuances of Omron PLCs and staying current with software capabilities can prevent many compatibility issues.

Best Practices for Long-Term Compatibility and Performance

- Strategic Upgrading: Upgrade your systems strategically, not just for the sake of having the latest software. Consider the benefits and potential challenges of each update or upgrade.

- Develop a Compatibility Roadmap: Create a roadmap for your PLC systems, outlining when and how upgrades and updates will be implemented. This planned approach helps in maintaining compatibility and minimizing disruptions.

Case Studies and Success Stories

Real-World Examples of Resolving Compatibility Issues

- Manufacturing Plant Upgrade: A case study from a manufacturing plant that upgraded its Omron PLC system to enhance production efficiency. They faced initial compatibility issues with their existing machinery. By working closely with Omron’s technical support and conducting thorough testing, they were able to resolve these issues, leading to a 20% increase in production efficiency.

- System Integration Success: Another success story involves a logistics company integrating new conveyor systems controlled by Omron PLCs. They experienced data communication challenges initially. The solution involved updating the PLC software and reconfiguring some network settings, which resulted in smoother operations and reduced downtime.

Lessons Learned and Practical Insights

- Detailed Planning: Both cases highlight the importance of detailed planning and consultation with experts before undertaking major upgrades or integrations.

- Flexibility and Adaptation: Being flexible and ready to adapt strategies based on real-time findings was crucial in resolving issues effectively.

Which Software is Used for Omron PLC Programming?

The primary software used for programming Omron PLCs is CX-Programmer, which is part of Omron’s integrated software suite, CX-One. CX-Programmer is designed for the development of PLC programs for Omron’s PLC series. It offers an intuitive interface with advanced functions like simulation and debugging to facilitate efficient programming and system management. Additionally, for newer PLC models, Omron has introduced Sysmac Studio, an integrated development environment that provides comprehensive support for programming, configuration, simulation, and monitoring.

What Programming Language Does the Omron PLC Use?

Omron PLCs typically utilize standard programming languages defined by the IEC 61131-3 standard. These include:

- Ladder Diagram (LD): A graphical programming language, which is widely used and easily understandable, especially for those familiar with electrical circuits and relay logic.

- Structured Text (ST): A high-level textual programming language, resembling languages like Pascal, which is used for complex algorithms and data manipulation.

- Function Block Diagram (FBD): A graphical language that uses blocks to represent functions, particularly useful for complex control processes.

- Sequential Function Chart (SFC): Ideal for sequential control processes, it represents the flow of operations graphically, making it easier to understand and manage sequential operations.

- Instruction List (IL): A low-level textual language, similar to assembly language, used by some programmers for fine-grained control over the PLC operations.

How Do I Connect to Omron PLC?

Connecting to an Omron PLC for programming or troubleshooting typically involves the following steps:

- Hardware Connection: Use a USB or serial cable to connect your computer to the PLC. For some models, an Ethernet connection may be used.

- Software Configuration: Open CX-Programmer or Sysmac Studio on your computer. Configure the software to recognize the PLC model and the type of connection you are using.

- Establish Communication: In the software, establish communication with the PLC. This may involve selecting the COM port for serial connections or specifying the IP address for Ethernet connections.

- Online Mode: Once the PLC is recognized by the software, switch to the ‘Online’ mode to interact with the PLC. You can now upload, download programs, monitor, and modify PLC parameters.

- Troubleshooting Connections: If the connection fails, check for issues like incorrect cable types, wrong communication settings, or driver problems. Refer to Omron’s technical documentation for detailed guidance.

Conclusion

In an era where technology rapidly evolves, staying proactive in managing Omron PLC software is imperative for maintaining operational efficiency, reducing downtime, and ensuring long-term system reliability.

Regular updates, strategic planning, and continuous learning are key to navigating the complexities of Omron PLC systems. Remember, the efficiency and success of your industrial automation heavily rely on the harmonious interplay of software and hardware.

Don’t let the potential of your automation systems remain untapped. Elevate your industrial performance today by embracing the advanced solutions and expertise we offer in Omron PLC technology. Reach out to us [info@ikwoco.com] to discover how our services can transform your operational efficiency and reliability.