What is CX-Programmer Used For?

CX-Programmer is a comprehensive tool designed for programming OMRON PLCs. It’s used for creating, testing, and maintaining programs associated with various OMRON PLC series. This tool supports PLC device and address information and facilitates communication with OMRON PLCs across supported network types.

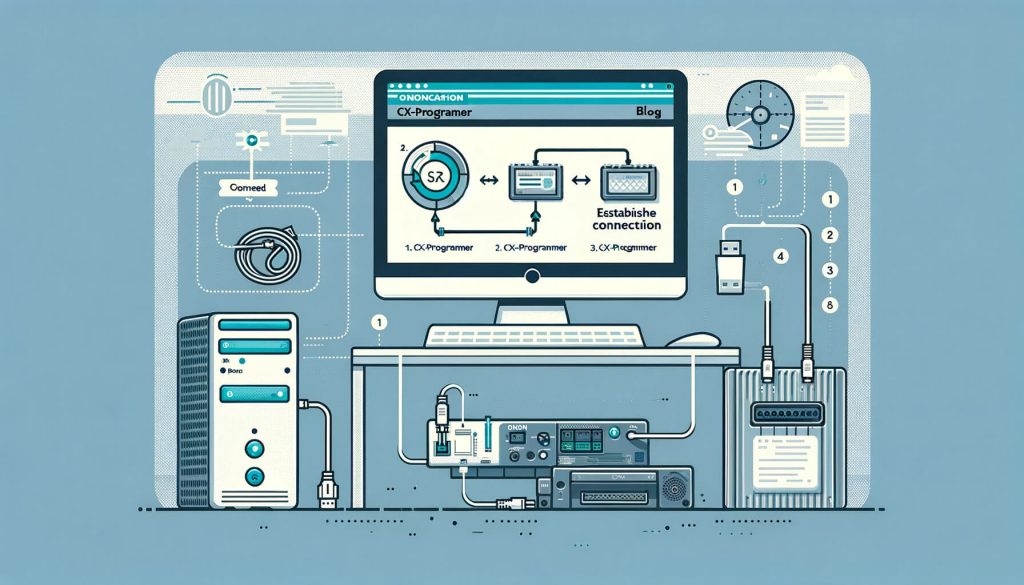

Downloading Programs to OMRON PLC

Step 1: Select the PLC Object

Start by opening the CX-Programmer and selecting the PLC object within your project workspace. This is your initial step in establishing a connection with the specific PLC you’re working on.

Step 2: Connect to the PLC

Click the ‘Work On-line’ button found on the toolbar. A confirmation message will pop up. Click ‘Yes’ to establish a connection with the PLC.

Step 3: Download the Program

After successfully connecting, choose the ‘Transfer To PLC’ button on the toolbar. This action opens the Download Options dialog. Here, you can select specific components such as program settings and the IO table to download. For CS/CJ/CP series PLCs, it’s also possible to save symbol definitions to the PLC. Finally, set your desired settings and click ‘OK’ to initiate the download.

Uploading Programs from OMRON PLC

Step 1: Select the PLC Object

In the CX-Programmer, begin again by selecting the PLC object from your project workspace.

Step 2: Go Online with the PLC

Click the ‘Work On-line’ button on the toolbar. Confirm your intention to connect by selecting ‘Yes’.

Step 3: Upload the Program

Now, choose the ‘Transfer from PLC’ button. A dialog will warn that the current program in the project will be overwritten. In the Upload Options dialog, you can select individual components, like the program or memory settings, to upload from the PLC. This feature is particularly useful for uploading specific sections of a program for online editing.

Advanced Feature: Partial Transfer – Task Transfer

For advanced users working with CS/CJ-series CPU Unit Ver. 2.0 or later, the ‘Partial Transfer – Task Transfer to PLC’ option is a game-changer. It allows you to download specific tasks, enhancing efficiency, especially in team environments. This method is ideal for making targeted changes without affecting the entire program.

What are the system requirements for CX Programmer?

To ensure smooth operation, CX-Programmer has specific system requirements:

Reference for Installation: Consult the CX-One Setup Manual for detailed system requirements. Memory Capacity: RAM requirements depend on the size of the programs created. For instance: 30 Ksteps or less: Minimum 60 Mbytes. 120 Ksteps or less: Minimum 240 Mbytes. 400 Ksteps or less: Minimum 800 Mbytes. Functional Restrictions: On Windows Vista or later OS, certain functional restrictions apply, particularly regarding online connections to PLCs on various networks like Controller Link, SYSMAC LINK, SYSMAC NET, and others.

What are the data types in CX Programmer?

CX-Programmer supports a range of data types, each with its format and size:

BOOL: 1 bit, used for logical binary values like contacts and coils. CHANNEL: 1 or more words, for non-bit values. DINT: 2 words, double integer, binary format. INT: 1 word, integer, binary format. LINT: 4 words, long integer, binary format. REAL: 2 words, floating-point number in 32-bit IEEE format. LREAL: 4 words, floating-point number in 64-bit IEEE format. UDINT, UDINT_BCD, UINT, UINT_BCD, ULINT, ULINT_BCD: Various formats for unsigned integers and BCD integers. WORD, DWORD, LWORD: Bit strings of 16, 32, and 64 bits respectively. TIMER: Used for timers in specific CPU units and software versions.

These data types ensure proper monitoring and appropriate use of symbols within the programming environment.

What programming language does the OMRON PLC use?

OMRON PLCs primarily use a form of ladder logic for programming. This graphical language represents electronic circuits and is widely used in industrial environments for controlling processes. It’s a user-friendly way for engineers and technicians to implement and troubleshoot control logic in PLC systems.

Conclusion

Mastering these steps is crucial for ensuring smooth operations in industrial automation. By following this guide, you can confidently manage your OMRON PLC programs, whether it’s for maintenance, updates, or troubleshooting. Remember, the key to successful program management lies in understanding your tools and processes.

For further assistance or inquiries about Omron industrial control products, feel free to contact me at info@ikwoco.com.