1. Utilize the Error Log Feature Effectively

Omron PLCs, like the CJ series, come equipped with an error log feature. This tool is invaluable for diagnosing issues. It records error codes and descriptions, providing a clear starting point for troubleshooting.

- Strategy: Regularly check the error log for any recorded issues. Look up the error codes in the Omron manual for detailed explanations and suggested fixes.

2. Keep Your Firmware Updated

Outdated firmware can lead to a host of programming problems. Manufacturers frequently release updates that fix bugs and improve performance.

- Strategy: Regularly check for firmware updates on the Omron website. Ensure your PLC’s firmware is up-to-date to prevent issues related to software glitches.

3. Master the PLC Setup and Configuration

Incorrect setup and configuration of your Omron PLC can lead to operational issues. It’s crucial to understand the intricacies of PLC settings.

- Strategy: Spend time learning about different PLC settings in the manual. Correctly configure your CPU unit, I/O settings, and network configurations as per the project requirements.

4. Implement Proper Installation and Wiring

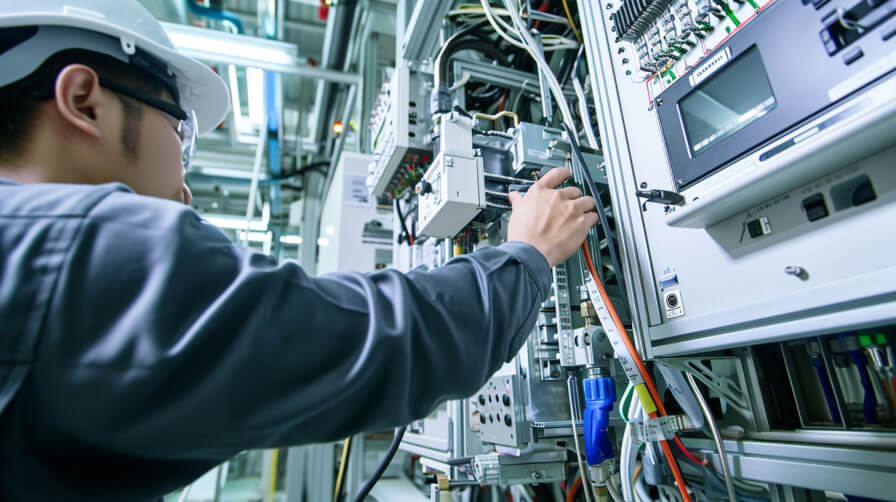

Faulty installation and wiring are common culprits behind programming issues. This can range from incorrect connections to inadequate power supply.

- Strategy: Follow the Omron operation manual strictly for installation and wiring guidelines. Regularly inspect and maintain wiring connections to ensure they are secure and correct.

5. Leverage Simulation Tools

Before implementing your program on the actual PLC, use simulation tools. These tools help identify logical errors and optimize program performance without risking hardware.

- Strategy: Utilize Omron’s PLC simulation software to test your programs. This allows you to rectify errors in a controlled environment, saving time and resources.

6. Regular Maintenance and Inspection

Regular maintenance is key to preventing programming issues. This includes checking battery life, inspecting hardware, and cleaning components.

- Strategy: Schedule regular maintenance checks. Replace batteries as needed, clean dust and debris, and inspect for any physical damages to the hardware.

7. Utilize Technical Support and Community Forums

When you’re stuck, reaching out for help can be a game-changer. Omron provides technical support, and there are numerous online forums where you can seek advice.

- Strategy: Don’t hesitate to contact Omron’s support for complex issues. Participate in forums and online communities for additional insights and solutions.

How Can I Improve My PLC Programming?

Improving your PLC programming skills involves a blend of continuous learning, practical application, and understanding the nuances of your PLC system.

- Practice Regularly: The more you program, the better you become. Regular practice helps you understand various functions and instructions deeply.

- Stay Updated: Keep abreast of the latest programming trends and updates in Omron PLC technology. Attend webinars, read industry publications, and participate in workshops.

- Learn From Mistakes: Analyze any errors you encounter. Understanding what went wrong and how to fix it deepens your programming knowledge.

How to Solve PLC Problems?

Solving PLC problems effectively requires a structured approach:

- Error Log Analysis: Utilize the error log feature of your Omron PLC to identify and understand the nature of the issue.

- Firmware Updates: Ensure your PLC’s firmware is up-to-date, as this can resolve many operational glitches.

- Systematic Troubleshooting: Follow a step-by-step troubleshooting process as outlined in the Omron manual. This might include checking installations, wiring, and configurations.

- Seek Support: When in doubt, consult Omron’s technical support or engage with online community forums for guidance.

What is the Best Way to Learn PLC Programming?

The best way to learn PLC programming is a combination of theoretical study and practical application:

- Structured Learning: Start with foundational courses in PLC programming, either online or through educational institutions.

- Hands-On Practice: Use simulation tools provided by Omron or work on small real-world projects to apply what you’ve learned.

- Community Engagement: Join forums and discussion groups. Learning from the experiences of others can provide valuable insights and shortcuts to mastering PLC programming.

What is the Most Efficient PLC Programming Language?

The efficiency of a PLC programming language can vary depending on the application. However, Ladder Logic is widely recognized for its simplicity and effectiveness, especially for those new to PLC programming. For more complex applications, languages like Structured Text or Function Block Diagram might be more suitable. Omron PLCs support multiple languages, so choosing the most efficient one depends on the specific requirements of your project and your comfort level with each language.

Conclusion

Resolving Omron PLC programming problems requires a strategic approach, combining technical understanding with practical solutions. By following these strategies, you can enhance your troubleshooting skills, ensuring smoother operations and fewer disruptions.