Understanding the Importance of Preventive Maintenance

Preventive maintenance is not just a routine check; it’s a strategic approach to avoid unexpected downtime and costly repairs. By regularly inspecting and servicing your Omron CJ1 systems, you can identify potential issues before they escalate, ensuring that your operations run smoothly and efficiently.

The Core of CJ1 Maintenance: Regular Inspections

1. Power Supply Check: Start by ensuring the voltage at the power supply terminals is within the acceptable range. The Omron CJ1 series is designed to operate within specific voltage limits, so consistent power supply checks are crucial.

2. I/O Power Supply Assessment: Similar to the source power supply, the I/O terminals need to be checked for voltage fluctuations. Stable I/O power is vital for the seamless operation of your system.

3. Environmental Monitoring: The operating environment significantly affects the longevity of your CJ1 system. Keep the ambient temperature within 0 to 55°C and humidity between 10% to 90%. Also, ensure the system is not exposed to direct sunlight, corrosive gases, or flammable materials.

Proactive Component Checks

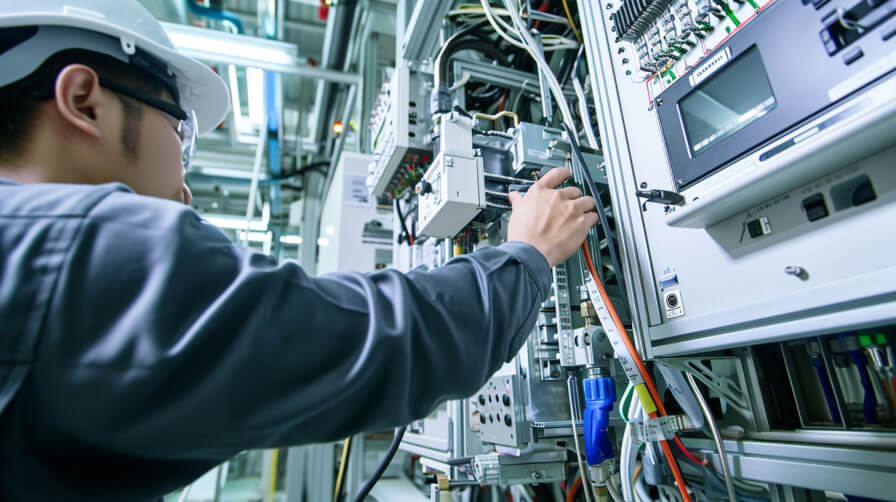

4. Installation and Wiring Integrity: Loose connections can lead to failures. Regularly check each unit’s connections and ensure that cable connectors are fully inserted and locked.

5. User-Serviceable Parts: Certain components like the backup battery have a finite lifespan. For the CJ1 series, the battery’s maximum service life is about five years at 25°C. Replace the battery proactively to avoid data loss.

Advanced Inspection Techniques

6. Noise and Vibration Analysis: High levels of noise and vibration can disrupt the normal functioning of your CJ1 system. Use advanced tools like oscilloscopes or synchroscopes to detect and mitigate these issues.

Tackling Common Issues in CJ1 Systems

7. CPU Unit Troubleshooting: If you encounter issues with the CPU unit, start by checking the power supply and connections. Refer to the Omron CJ1 Operation Manual for detailed error codes and troubleshooting steps.

8. I/O Unit Maintenance: Regularly inspect the I/O units for signs of wear and tear, such as damaged cables or loose terminals.

9. Software Updates and Backups: Keep the system’s software up-to-date and regularly backup your configurations and programs.

Best Practices for Long-Term Maintenance

10. Keep a Maintenance Log: Document every inspection, repair, and replacement. This historical data can be invaluable for diagnosing future issues.

11. Train Your Team: Ensure that your maintenance team is well-trained in handling Omron CJ1 systems. Proper training can prevent errors and increase the efficiency of your maintenance processes.

12. Partner with Professionals: Sometimes, the best maintenance strategy involves professional support. Consider partnering with certified Omron professionals for periodic checks and complex troubleshooting.

The Role of Preventive Maintenance in System Longevity

By adhering to these preventive maintenance steps, you not only enhance the performance of your Omron CJ1 systems but also extend their operational life. Remember, preventive maintenance is an investment that pays off by reducing downtime and saving costs in the long run.

Conclusion

Preventive maintenance for Omron CJ1 systems is an essential practice that every industrial automation professional should prioritize. By following these guidelines and incorporating regular checks into your routine, you can ensure that your Omron CJ1 systems continue to operate at peak performance, contributing significantly to the overall productivity and efficiency of your operations.

For more detailed information on maintaining Omron CJ1 systems, refer to the Omron CJ1 Operation Manual.

Remember, the key to successful preventive maintenance lies in consistency, attention to detail, and a proactive approach. Keep these principles in mind, and your Omron CJ1 systems will thank you with years of reliable service.