Understanding PLCs and Their Importance

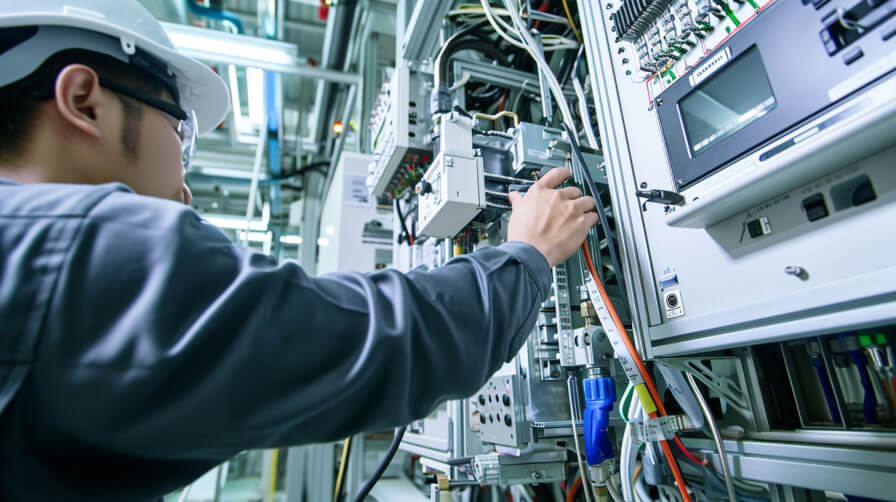

Before diving into Omron PLCs, it’s essential to understand what PLCs are and why they are pivotal in industrial automation. PLCs are digital computers used for automation of various industrial processes like control of machinery on factory assembly lines. They are designed to withstand harsh conditions and perform a range of control functions where reliability and precision are paramount.

What are the advantages of Omron PLC?

Reliability and Durability: Renowned for their robust construction and long-term reliability. Flexibility and Scalability: Easily adaptable to a range of industrial needs, with scalable options for different applications. Advanced Features: Incorporate cutting-edge technology for precise control and automation. User-Friendly Programming: The CX-Programmer software ensures a smooth programming experience. Wide Communication Compatibility: Supports various communication protocols, enhancing integration capabilities.

Key Factors to Consider When Selecting an Omron PLC

1. Understanding Your Requirements

- Application Scope: Define the complexity and scale of your application. Do you need a PLC for simple machine control, or for managing a complex industrial process?

- Environmental Conditions: Consider the environmental conditions where the PLC will operate. Omron PLCs are built to withstand various industrial environments, but selecting the right model for your specific conditions is crucial.

2. Technical Specifications

- I/O (Input/Output) Capacity: Estimate the number of inputs and outputs required. Omron PLCs come in various I/O configurations to suit different needs.

- Memory and Processing Speed: Ensure the PLC can handle your application’s data processing needs. Higher memory and faster processors are necessary for more complex applications.

- Communication Protocols: Verify compatibility with existing systems. Omron PLCs support various communication standards, ensuring seamless integration.

3. Expansion and Compatibility

- Scalability: Consider future expansion needs. Omron PLCs offer flexibility in terms of scalability.

- Compatibility with Existing Systems: Ensure the new PLC can integrate with your existing machinery and software systems.

4. Ease of Use and Programming

- User Interface: Omron PLCs come with user-friendly interfaces for easier programming and operation.

- Software Support: Omron provides robust software tools for efficient programming and troubleshooting.

5. Quality and Reliability

- Brand Reputation: Omron is known for its quality and reliability, a crucial factor in PLC selection.

- Warranty and Support: Check the warranty and technical support offered by Omron.

Omron PLC Series Overview

Omron offers a range of PLCs designed to meet various industrial requirements. Here’s a quick overview of some popular series:

1. CP Series

Ideal for small to medium-scale control applications. They are compact, cost-effective, and easy to install and operate.

2. CJ Series

Suitable for medium to large-scale applications. They offer high processing speeds, large memory, and extensive I/O capacity.

3. NX/NJ Series

Designed for advanced automation needs. These PLCs provide high-speed processing, integrated motion control, and support for IoT connectivity.

4. CS Series

Best for complex and demanding applications. These PLCs offer robust performance, large program capacities, and support for multiple communication protocols.

Real-World Applications and Case Studies

To illustrate the practicality of Omron PLCs, let’s look at some real-world applications:

- Automotive Industry: Implementing Omron PLCs for assembly line automation, ensuring precision and efficiency.

- Food and Beverage: Using Omron PLCs for packaging and processing, enhancing hygiene control and productivity.

- Pharmaceuticals: Omron PLCs are employed in the precise control of pharmaceutical manufacturing processes.

Which Software to Use with Omron PLC?

Omron PLCs are typically programmed using CX-Programmer, part of the CX-One software suite. This integrated software enables easy programming, configuration, and monitoring of Omron PLC systems. The software’s user-friendly interface and advanced features make it an excellent choice for both beginners and experienced users.

What Protocol Does Omron PLC Use?

Omron PLCs commonly use the EtherNet/IP and FINS communication protocols. EtherNet/IP is used for industrial Ethernet communication, allowing for easy integration with other Ethernet-compatible devices. The FINS protocol is used for communication within Omron networks, ensuring efficient data exchange between Omron devices.

What is the Name of Omron SCADA Software?

The SCADA software for Omron PLCs is called CX-Supervisor. It is designed for building and managing advanced graphical interfaces for machine control, process control, and other automation applications. Omron PLCs are renowned for their quality, durability, and adaptability. They are designed to meet diverse industrial needs, making them suitable for a wide range of applications. From small-scale operations to complex industrial systems, Omron provides solutions that enhance efficiency and productivity.

FAQ

Q1. Can Omron PLCs be integrated with other brand devices?

A1. Yes, Omron PLCs support various communication protocols, making them compatible with many other brand devices.

Q2. Are Omron PLCs suitable for harsh industrial environments?

A2. Absolutely, Omron PLCs are designed to withstand harsh industrial conditions, including extreme temperatures and vibrations.

Q3. How user-friendly is the programming of Omron PLCs?

A3. Omron PLCs are known for their user-friendly interfaces and robust software support, making programming and operation simpler and more efficient.

Q4. What kind of technical support does Omron provide for their PLCs?

A4. Omron offers comprehensive technical support, including online resources, software updates, and expert assistance.

Conclusion

Selecting the right Omron PLC involves careful consideration of your specific needs and the technical specifications of the PLC. Understanding your application requirements, considering the scalability, ensuring compatibility, and focusing on ease of use and reliability are key to making an informed decision. With a wide range of series and models, Omron offers PLC solutions that cater to various industrial automation needs, ensuring efficiency, reliability, and innovation.